Haute qualité En10305 Cold Drawn Precision Seamless Steel Tube / Pipe

Description du produit

Product Name |

E215 steel pipe |

E235 steel pipe |

E355 steel pipe |

chemical analysis |

C: 0.10;Si: 0.05;Mn: 0.70;P: 0.025; S: 0.025;Al: 0.025 |

C: 0.17;Si: 0.35;Mn: 1.20;P: 0.025; S: 0.025 |

C: 0.22;Si: 0.55;Mn: 1.60;P: 0.025; S: 0.025 |

Tensile Strength |

+C, 430MPa; +LC, 380MPa;+SR, 380MPa;+A, 280MPa;+N,290-430MPa |

+C, 480MPa; +LC, 420MPa;+SR, 420MPa;+A, 315MPa;+N, 340-480MPa |

+C, 640MPa; +LC, 580MPa;+SR, 580MPa;+A, 450MPa;+N,490-630MPa |

Yield strength |

+SR, 280MPa; +N, 215MPa |

+SR, 350MPa; +N, 235MPa |

+SR, 450MPa; +N, 355MPa |

Standard |

EN10305-1 |

||

Length |

As customer s request |

||

Packaging |

Standard export packing, packed in woven bags, with two nylon slings, or can be customized as request |

||

Heat Treatment/ Delivery Condition |

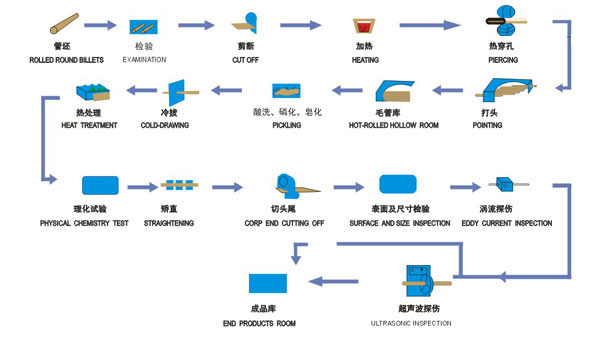

Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation

The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding)

Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree.

The last Cold forming process is followed by annealing in a controlled atmosphere.

The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

||

Delivery Time |

Within 35-50 days from receiving deposit |

||

Payment Term |

100% L/C at sight or 30% deposit, 70% balance against copy of B/L |

||

Usage/Application |

Pipes for automobile and motorcycle |

||

Main Market |

Asia, Middle East, Europe, etc. |

||

Epaisseur de paroi: 2-50mm

Matériel: ST52, Q345B, CK20, CK45, SAE1026

Standard: GB / T8713-88, GB / T3639-2009, DIN2391, EN10305

Cold Drawn Tube peut être produit selon les exigences des clients que le degré de précision peut atteindre H9 / H11.

Composition matérielle et chimique

DIN2391 standard ST52, EN10305 standard E355, 16Mn, ASTM A106B, C20 / 20 #, CK45

Groupes de Produits : Tuyaux en acier de précision > Tuyau d'acier automobile

Premium Related Products